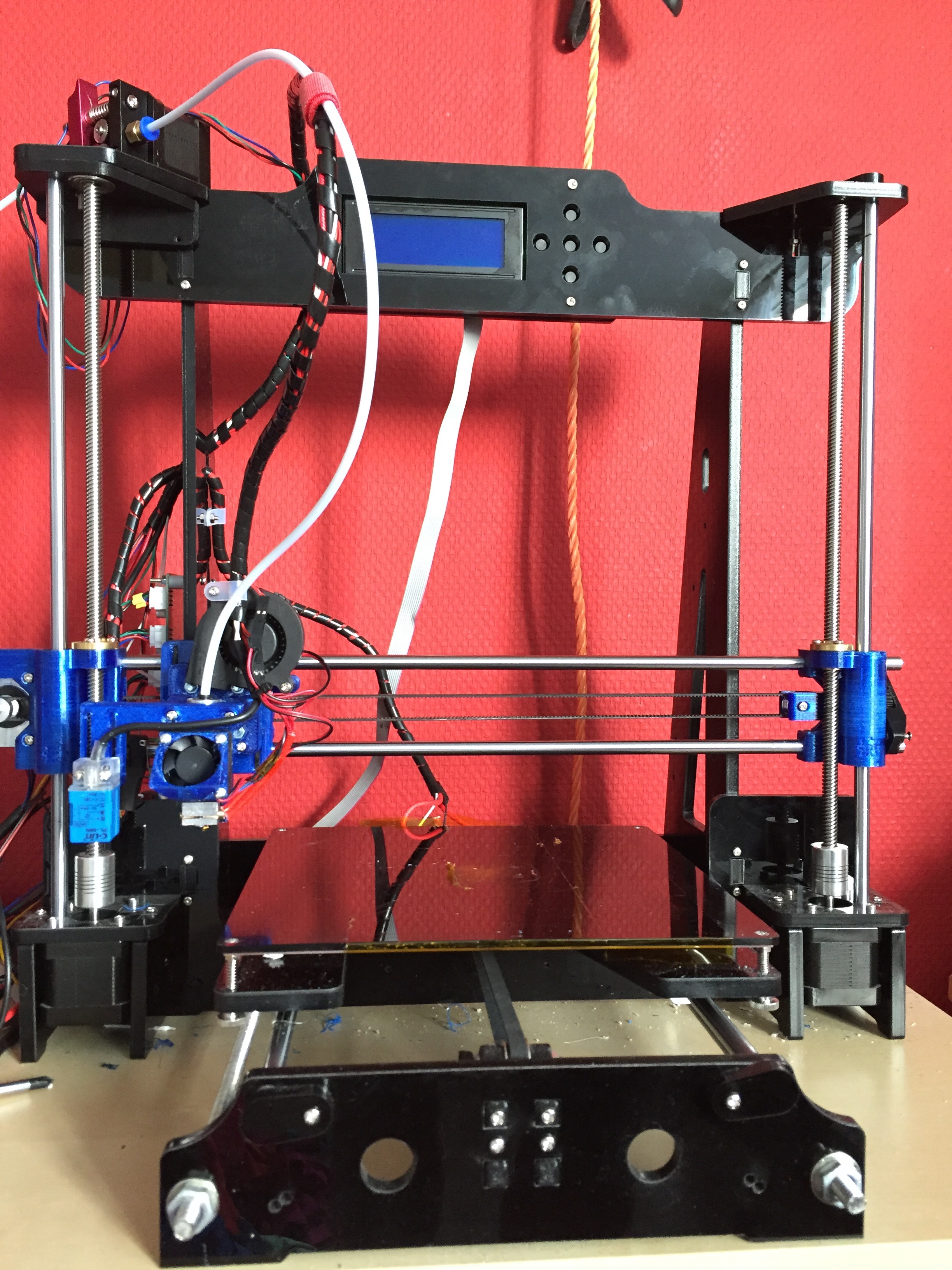

3D Printing

I just love 3D printing, I never thought that it would be so much fun, because we have a 3D printer at work but rarely use it, I never gave it too much attention.

Now that I have my own printer it feels like I can make all the silly things I wanted to try or fiddle with but never felt like it was worth spending too much money one to have made.

Also the fact that you can upgrade, repair, change fiddle and calibrate the device is very appealing to me

My Printer’s specs

| Brand | TronXY |

| Type | Prusa i3 |

| Extruder | E3D V6 |

| Heated bed | yes |

| Firmware | Marlin |

| HAL Sensor | PL-08N |

Firmware

The firmware I use on this printer

Calibration

Filaments

Real® Filament PET-G Translucent blue

- Print on Kapton tape, with heated bed at 80 °C

- Extruder temp: 235 °C

- Speed: 60 mm/s²

Manufacturer supplied PLA black

- Print on Kapton tape, with heated bed at 60 °C

- Extruder temp: 195 °C

- Speed: 60 mm/s²

Manufacturer supplied ABS black

- Print on Kapton tape, with heated bed at 105 °C

- Extruder temp: 220 °C

- Speed: 60 mm/s²

Purement antibacterial PLA white

- Haven’t tried this yet will update as soon as I can

- Print on Kapton tape, with heated bed at ? °C

- Extruder temp: ? °C

- Speed: ? mm/s²

Upgrades

The number of upgrades is becoming significant so I dedicated a page to them

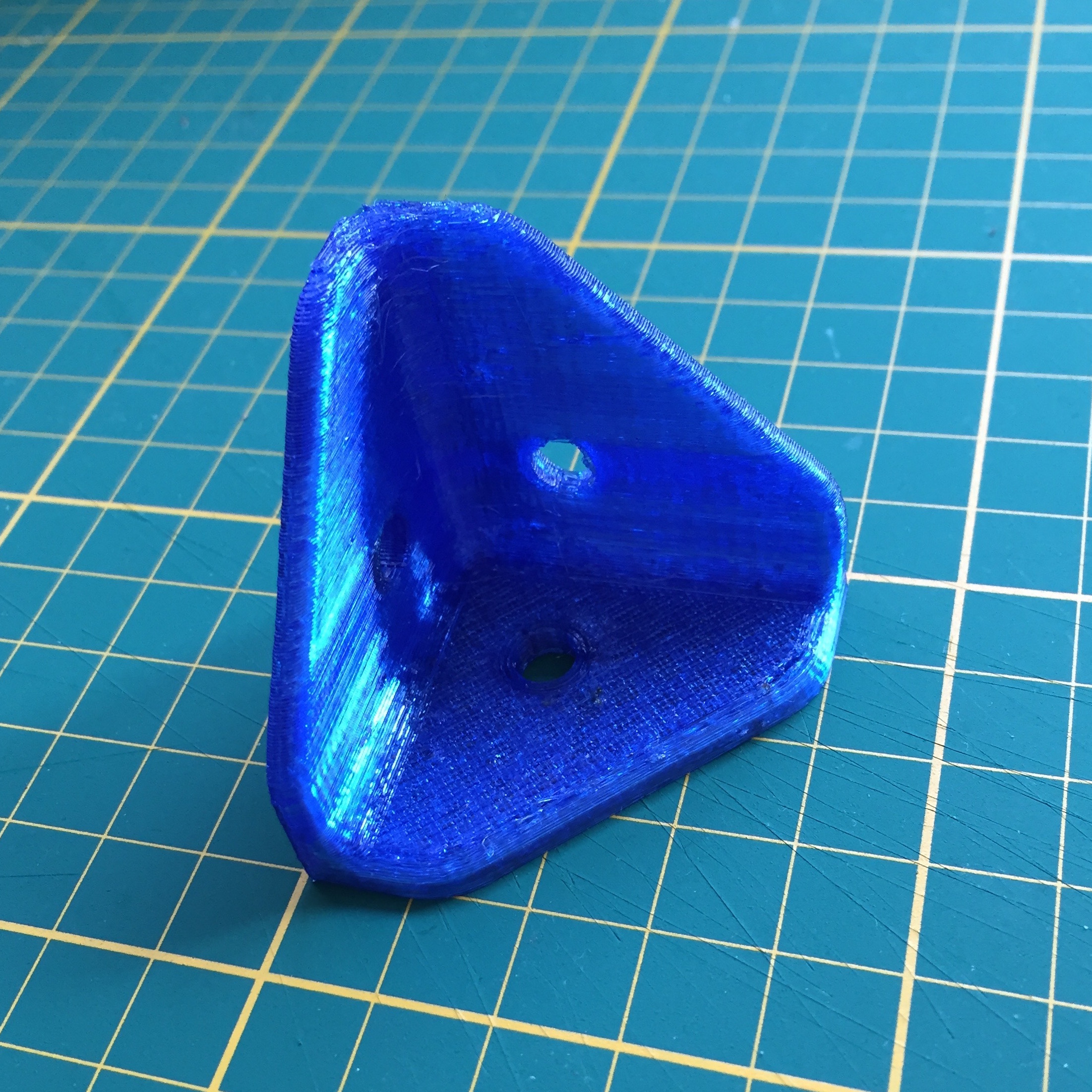

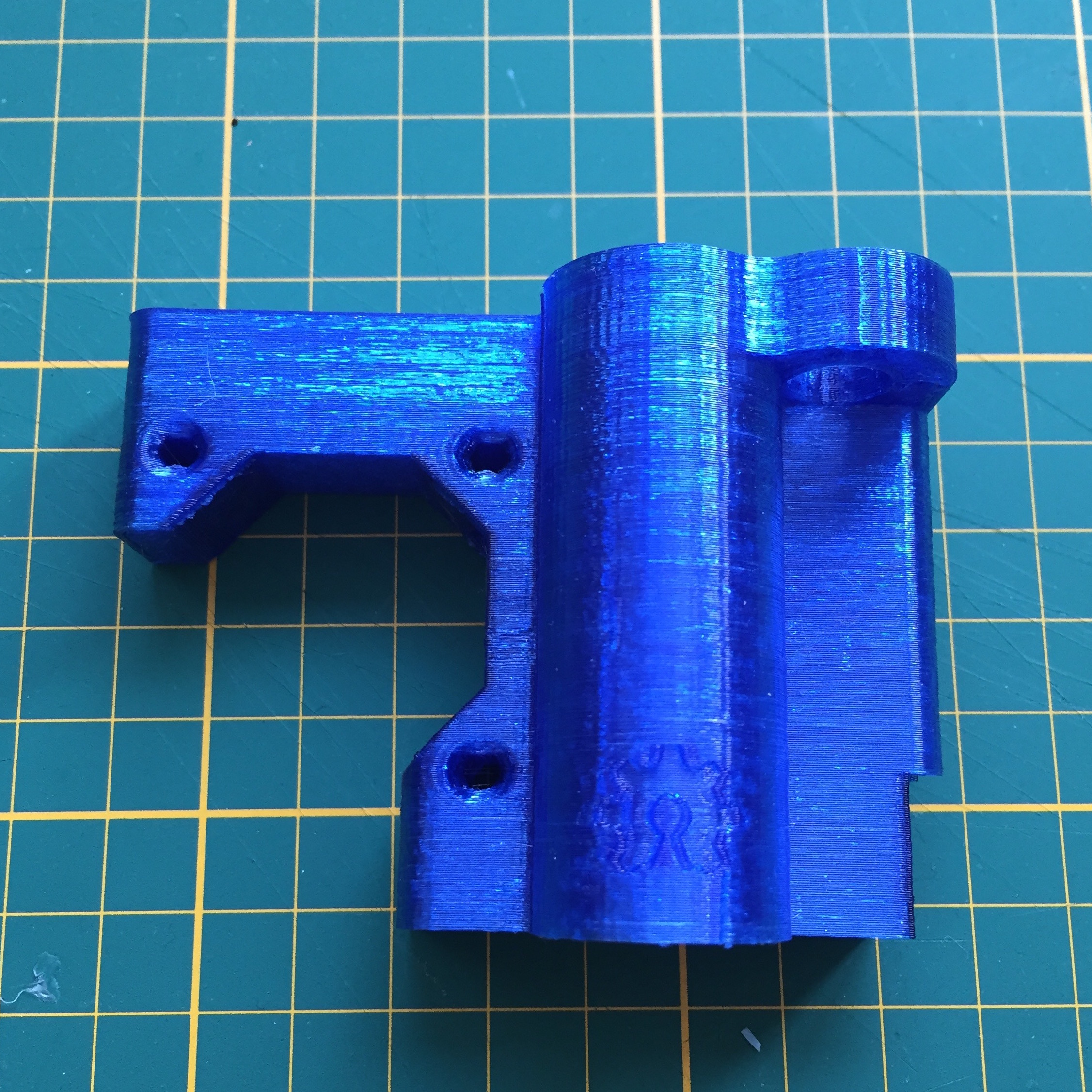

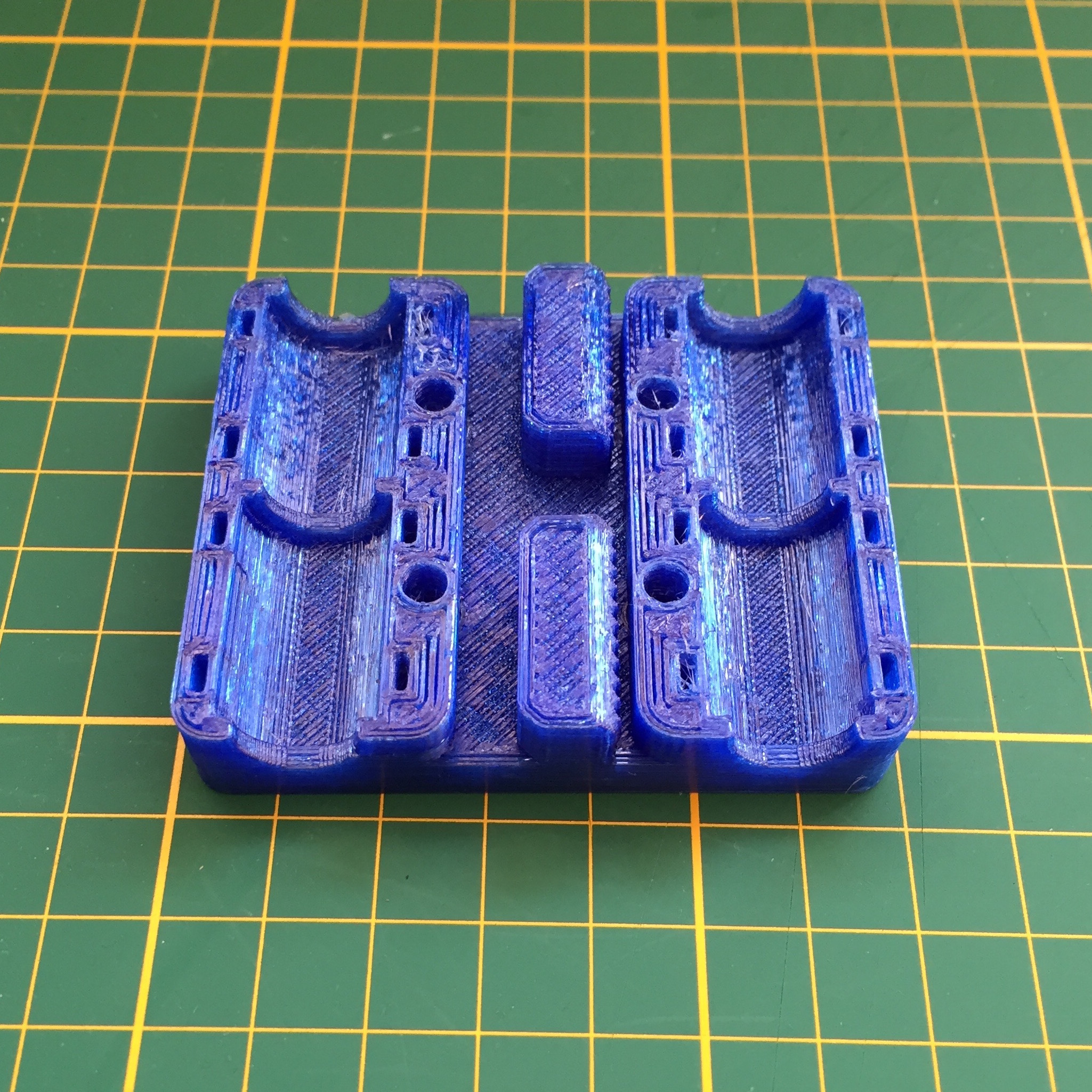

Printed objects

Most of my designs can be found on Thingyverse I use Autodesk Fusion 360 for designing